After several regional events the Cayman’s first two national events were the Bristol Pro followed by the Bristol Tour. The situation with the car was this: stock struts equipped with high-rate bumpstops plus the Tarret 26.8mm 5-hole front bar set to the middle set of holes. Negative camber is maxed out all around (about 1 degree in the front and 1.5 or so in the rear), front toe is zero and the rear is toed in a total of 1/8″. Bridgestone RE71RS tires in 18 by 255/285.

Below is what the front bumpstop stack looked like. With the spacers and some slight trimming the stack is exactly the same height as the stock bumpstop. I estimate the stock bumpstop at 75lb/in. The stack of three blacks provide 350lb/in.

Notice the shape of the black polyurethane donuts. They begin with limited surface area in contact, but as they compress the surface area rapidly increases. I think this provides an initially soft rate and explains why I never feel the point of contact.

In any case the setup didn’t work well at all on that bumpy site. While it was well balanced with moderate oversteer, in places the car was bouncing like a bucking bronco. I placed 25th out of 31. The only good news was that I made significant progress in learning how to launch the car: use a very high rpm clutch dump.

The Bristol Tour was only slightly better. I was 24th of 34. I managed to beat a few people that had beaten me in the Pro, but it was small consolation. I also lost badly to someone I had beaten the week before at a super-smooth site. The good news is that the car ran perfectly, nothing broke and it was clear where the major problem lay: insufficient low-shaft-speed damping.

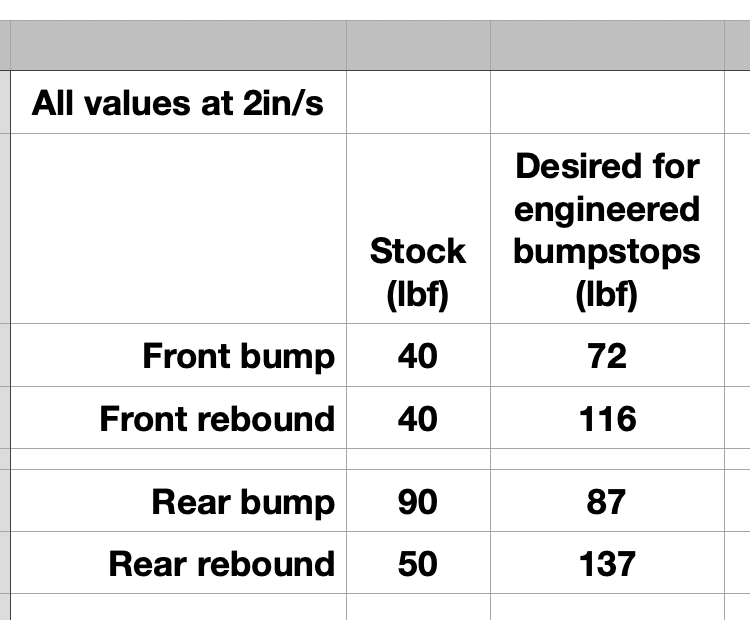

Below is a comparison of forces provided by the stock struts at 2in/s shaft velocity to what I think is needed. Except for rear bump the stock values are insufficient to control the sprung mass. This is to be expected since the bumpstops massively increase the effective spring rate. By the way, the “desired” values take into account the resilience of the polyurethane when calculating rebound forces, that is, the fact that the bumpstops have significant internal damping and return at most 65% of the applied energy. If I didn’t take this into account I would end up with too much rebound force once I install revalved B6 struts.

After Bristol I was able to install the Bilstein B6 struts, but with the damping provided by Bilstein.

The first hurdle was to modify the front struts to get them legal per SCCA street class length rules. The extended length was about 0.4″ longer than the allowed 1″ longer than stock. An easy solution was found that shortened the extended length without having to open up the damper and without having to cut and rethread the hardened shaft.

The solution was to drill out the threads in the bottom of the housing where the shaft attaches and weld on a spacer and a new nut. This pulls the shaft attachment point down to reduce the extended length. The effect is to reduce the increased droop travel that the B6 has over the stock B4 strut. Prior to welding it looked as below.

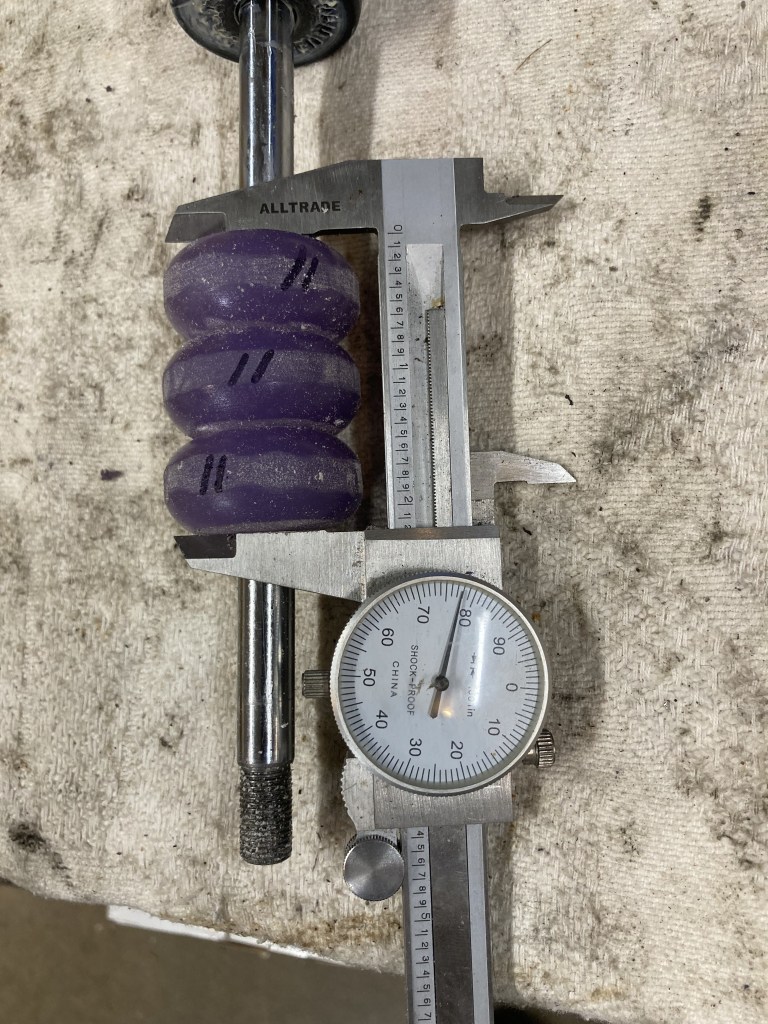

The second issue was to engineer a completely new set of bumpstop stacks that would work with the B6 inverted design. The B6 shaft is only 11mm in diameter, much smaller than the B4 front and rear shafts so the polyurethane donuts I used before which had 5/8″ ID holes wouldn’t work. Plus, they were too big on the OD as well. The B6 carries the bumpstops internal to the housing. This means that I needed bumpstops with both smaller ID and smaller OD yet with the same spring rates as before.

Bumpstop Length Discussion And Word Of Warning

The Street class rules on bumpstops for struts contain the limitation that the length of the strut at the point where the bumpstop is contacted cannot be longer than stock.

Without this provision you could fill the motion gap with a longer bumpstop, allowing any street-class car to have any spring rate desired starting precisely at the static ride height. All cars in Street would immediately do this and obtain race-car stiffness, plus cause all sorts of issues with damping. (Ask me how I know!)

With this limitation the use of alternate bumpstops is limited by the manufacturer’s stock design. For cars that use the standard short and stiff bumpstops there is no ability to use the bumpstop as an auxiliary spring. It’s never contacted during normal running, even at the cornering limit. The Corvettes I’ve run in the past were like this.

The ND Miata in C-Street is not like the Corvette. Mazda designed the bumpstops to be contacted during cornering where they increase roll rate and affect lateral force distribution front to rear. Porsche did the same with the Cayman, just as they have done on most or possibly all of their sports cars starting in the 1980’s AFAIK and up through at least the 997/987 cars.

As a result, all the fully-prepped ND Miatas in C-Street that I have knowledge of use aftermarket bumpstops cut to various lengths. There seems to be a basic recipe for this strategy. I take it on faith that they are done in a legal manner.

There’s a catch, however, regarding bumpstop maximum length.

If the stock strut is used, or if an aftermarket strut is used that conforms exactly to certain key stock dimensions, then the maximum length of an aftermarket bumpstop is the same as the length of the stock bumpstop. That’s simple enough. This was the case with my Cayman when I was using the stock struts. I bought one each new stock front and rear bumpstop (since the originals were mostly powder) and measured them to establish the limits.

If the aftermarket strut is not dimensionally identical to the stock strut, however, then measurements must be taken and the maximum allowable length of the bumpstop must be calculated to assure meeting the provision in the rules above. This is not necessarily a simple task.

No manufacturer has any obligation to design aftermarket struts or shocks to meet SCCA autocross rules. In fact, they have every incentive to alter the design to provide better performance to justify their purchase. I know of more than one case where a well-respected supplier of aftermarket equipment for SCCA Street class has provided illegal equipment to unsuspecting clients.

In the case of the Bilstein B6 aftermarket strut, even though it’s a direct replacement for the stock B4, designed to use the stock spring and has the exact same spring perch location, it has other differences. After taking measurements and doing the calculations I found that the allowable bumpstop length for the fronts was almost 1” shorter than the stock bumpstop! That was very disappointing as I think longer is better even if the strut length at the point of contact is the same.

In the rear the allowable max length got slightly longer.

So, neither the front nor the rear allowable max bumpstop lengths for the B6 struts were the same as the stock bumpstops and I had to factor this into the new stack designs.

By the way, I carry a copy of the measurements and calculations in the glove compartment of the car if anyone desires to inspect it at an event.

New Bumpstops

I was able to find a smaller style of polyurethane donut, use a higher durometer formulation and physically alter the shapes to allow them to fit inside the lower housing of the strut and provide the desired stiffness.

The rear stack is shown above. Notice that material has been removed from the OD making the surface flat instead of oval. I removed 10% of the mass in an attempt to reduce the rate by 10%. Plastic spacers were used to get the total height up to the maximum allowed. I want contact to occur as early as legally possible because I’m trying to limit roll to reduce loss of negative camber.

The front stack is shown above. In this case the OD has been slightly trimmed for fitment and the mating surfaces have been trimmed to reduce the stack height to the maximum allowed, which is shorter than the rear for the B6 struts.

Chicago Tour

For the remainder of the season until after Nationals I installed 255/295 Yokohama A052 tires. I had trouble with my trailer, didn’t have time to diagnose it, so I drove the Cayman to Rt. 66 Raceway in Joliet, Illinois for the Chicago Tour. This was almost a disastrous decision.

The car seemed weird at the Tour. It was OK, but weird. It no longer made big vertical bounces, thanks to the increased damping in the B6 struts, but the car was jittery over sharp bumps and things were now limited by a distinct push, opposite the case at Bristol. I generally drove well, but it was a chore and the car made a strange noise in left turns. I placed 6 of 7, but was encouraged that my delta to the winner, the same winner as at Bristol, was a little bit smaller.

When I returned home I couldn’t get an appointment to have the front struts revalved before the next national tour event at Grissom. My shock guy was too backed up. He can’t work on them until after Grissom. (The rears will have to wait even longer.)

Just before leaving for the next event I removed the front wheels in order to reduce the front bar stiffness by one hole, hoping to decrease the understeer. I found black rubber on the underside of the spring perch on the right side. The perch paint had been rubbed off by gravel. Hmmm. There was essentially no clearance between the spring perch and the running surface at the top of the tire. I looked at the bottom of the strut and saw that it appeared to have contacted the lower ball joint stud. (See pic below.) The entire strut had obviously slipped position in the upright. That’s when I remembered.

I remembered that on the way to Joliet, in one of the 14 lane closures/construction zones along I-57 that I went through, I hit a sharp dislocation in the surface. It felt like a 3″ change in height and I was going ~60mph. There had been no warning signs. There was a large impact and a metallic clank from the right front. I watched the tire pressures to see if the tire had been damaged and felt for the vibration of a bent rim. All seemed OK. I breathed a sigh of relief.

In actuality the right front was now almost an inch low. The alignment and the corner balance had to be totally wonky. That was the condition for my runs at Chicago.

Once home I loosened everything and reset the strut to the stock position. The sheet-metal tab that normally indexes the stock position had been bent all to hell. I bent it back, expecting it to break, but it didn’t. I set the front bar less stiff and loaded the car onto the (repaired) trailer for Grissom. I didn’t have time to check the alignment.

Grissom

The car was better at Grissom… it was no longer weird. The understeer was lessened, but still there. The jitter over sharp bumps was still there.

The jitter is probably caused by excessive damping in the B6 struts. The B6’s have too much damping, especially at high velocity, in both bump and rebound, even when riding on the really stiff bumpstops I’ve installed. This excessive damping impairs grip, especially over sharp bumps. The unsprung masses are being over-controlled. I think these struts are damped to a level where even the most insensitive driver will exclaim on the first drive after installation, “Woah! What a difference!” That driver will probably never know how much grip at the limit has been sacrificed. And we worry about autocrossers screwing up their cars!

Once Day 1 was in the books I was in 3rd place of 7, the last trophy position. The big news is that I was much closer to the leader than before.

I was only 0.021s ahead of 4th, so it was a great battle on day 2. The car didn’t miss a beat but I slipped to 4th, still in front of two very good drivers in NDs plus an NC.

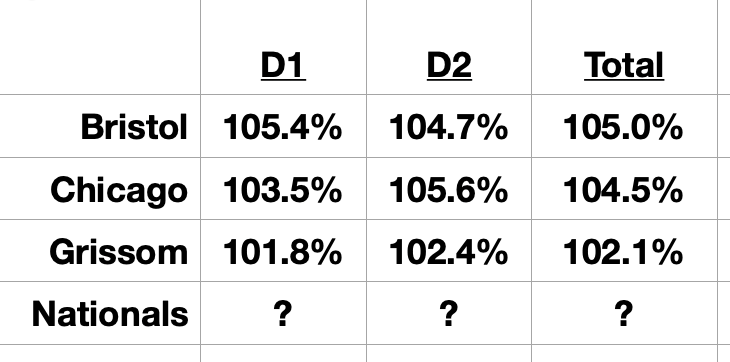

Here are the national tour results for the car the way I look at them:

What I’ve done above is to calculate the percentage slower I was each day than the leader, who was the same person at all three events and is probably the favorite for the jacket this year. At Bristol on day 1 I ran a time 105.4% of the winners time, so I was 5.4% slower. Similarly, I was 4.7% slower on day 2. That put me exactly 5% behind the leader for the two day total. That’s a long way back. That’s 24th of 34.

A Chicago, the first event on the B6 struts and Yokohama tires, I was marginally better. The wonky suspension may have been holding me back.

Then at Grissom there was a big leap forward. I know, it’s just one event, but the surface is very similar to Lincoln. By the way, the guy who took 3rd away from me on day 2 got the last trophy position in C-Street at Nationals last year.

The reason for tracking in this manner is because the goal for this year has always been to trophy at Nationals in C-Street with this car. Tracking these percentages is a way to answer the question: am I anywhere close?

Well, last year in C-Street at Nats the last trophy position was 2.4% behind the winner. In 2022 the last trophy position was 2.0% behind the winner. By way of comparison, last year I took the last trophy in B-Street. I was 1.9% behind the winner.

Judging by the Grissom result a trophy spot this year is within the realm of possibility. If revalving the front struts gives me some additional front grip that could make the difference.