Part 1- Estimating the Effect on Weight Transfer and Roll

I’m setting up a 1989 Porsche 944 with the sport suspension (Porsche option code M030) for street-class autocross. This suspension design, MacPherson strut in front with threaded spring perches and semi-trailing arm in the rear with indexable torsion bars, allows me to adjust the ride height of the car, i.e. I can lower it from stock. Figure 1 shows the front suspension, looking from the front.

Figure 1

Adjusting the front couldn’t be easier… just twist the spring perch. It’s right there at the base of the spring in the photograph.

Adjusting the rear is the opposite of easy. It’s so horrifying to contemplate that I really don’t want to talk about it. At least it can be done, which is an advantage this car has over many others.

Right now I’m in the middle of swapping M030 torsion bars for stock and re-indexing them, along with renewing all the bushings. I’m aiming at 1” lower than stock as the base setting. The car has a separate method for adjusting it slightly from the base position apart from indexing the bars. That method is intended mainly for corner balancing.

Before I go crazy with lowering the car I want to estimate how much cornering power I can expect to gain compared to the stock ride height and balance that advantage against certain disadvantages that will occur.

One thing people forget is that being able to quickly estimate an answer is just as important as being able to grind out a precise figure. For one thing, maybe the estimate is enough to tell you you’re going down a blind alley. For another, it allows you to know when your precise answer is obviously wrong because you made an error somewhere. (If I only had a nickel for every time a young engineer believed that his obviously (to me) wrong answer just has to be correct because, well, it just has to be because he spent so much time on it and it was derived exactly from first principles as taught in school. Usually, they come back with “I found a slight mistake… how did you know?”)

If anyone can show me where this information is already available for the 944, I’d sure like to see it! And, if you have better numbers than what I’ll be using, I’d love to have those too.

Lowering a 944 (and just about any other car) does two good things: 1) it creates an increase in the maximum available static negative camber, which is limited to much less than optimum for autocross in most cars as they come from the factory, and, 2) it reduces lateral weight transfer in the corners. Both of these effects tend to increase tire performance at the limit.

Lowering the 944 also has at least one quite bad effect, namely, a reduction in roll stiffness with the MacPherson strut front. I’ll explain why this happens as we go along.

Reducing the roll stiffness means the car rolls over to a greater angle than before in the corners. The extra roll reduces the negative camber of the outside tires (some of which was gained by lowering) just when you need it most, and tends to reduce the transient response of the car by making it take longer to go from full cornering in one direction to full cornering in the other direction. Transient response, while important in all forms of motorsport, is especially critical in autocross.

A race car that can change the springs can counteract this decrease in roll stiffness. In SCCA Street class autocross, I can’t change the springs to anything not offered stock and I can only change one anti-sway bar.

Now, there are things that might be done to limit the roll even in Street class (specially designed bump stops for this particular car) and to increase the transient response (increased low-shaft-speed damping in the shocks) but I’m not going to get into that here. Those are possible mitigation measures that also have their own trade-offs, though I expect to use both to some degree before it’s all over.

There are a lot of opinions floating around out there on the subject of lowering a 944. In general, the advice is to lower the car, but not too much. Some people scream, “Whatever you do don’t let the roll center go under the ground” and point to the angle of the lower control arm in the front suspension, saying it shouldn’t go below horizontal. (The roll center is the imaginary point that the sprung mass of the car rolls around when you enter a corner. Actually, there’s one for the front suspension, one for the rear. The roll axis connects the two.)

There may also be bump steer effects, which make a car hard to drive, tire rubbing possibilities and a concern with over-rotation at the lower ball joint which has the potential to crack the lower control arm.

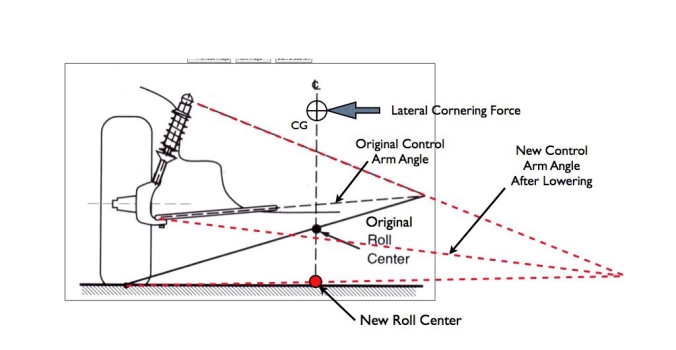

Figure 2, below, shows the relationships that determine the roll center for a generic MacPherson strut suspension. I’ve added some extra dashed lines to show what happens when the lower control arm angle is changed from slanting up toward the center of the car to slanting down without changing the strut angle. (In reality, the strut angle does change a little, making things even more complicated.)

Figure 2

What suspension designers call the roll center was termed in my mechanical drawing class an instantaneous center of rotation, or instant center for short. We learned to derive these for various linkages and mechanisms. The key point being it’s where it is for an instant, not forever. That is, the damn things move around when the suspension articulates. Lowering the 944 is an articulation of the suspension that moves the roll center. See how simple this will be?

Looking at figure 2, this is how you find the instant center called the roll center for a MacPherson strut mechanism:

1- draw a perpendicular from the top of the strut

2- draw a line parallel to the lower control arm

3- from where those two lines intersect draw a line to the tire contact patch

4- the roll center is at the intersection of that last line and the car’s centerline

The roll center is the point about which the sprung mass rotates at the start of cornering. As the car rolls, the roll center is actually going to move, maybe only a little, maybe not so little, but I’m going to have to ignore that.

I’ve also added a circle to mark the center of gravity (CG) of the sprung mass. When cornering, a lateral force acts on the sprung mass at that point. This is the big arrow in the figure. (The opposite reaction, not shown, is at the tire contact patch.)

That force causes the sprung mass to rotate about the roll center. The distance from the CG to the roll center is a moment arm. It’s a lever that’s working on the springs and bars. The longer the lever, the more the effect on roll for the same lateral force.

When the car is lowered the control arm angle changes. I’ve drawn a new one pointing downward. You can see that the new roll center is just about sitting on the ground. It’s quite possible that it descend below the ground, but only if the control arm angle slants even more sharply downward. (It may do this dynamically in a turn.)

With a control arm angle limited to horizontal the roll center can get close to the ground, but, because of the geometry, it can never descend below it. You might want to stare at the figure until that becomes clear.

What I haven’t shown is the new CG point. For the new control arm angle it will have dropped a little bit from where it’s shown. But, the way things work is that the roll center drops more than the CG point, so the length of the lever between them, the moment arm, gets longer as the car is lowered.

I think this is where the rule of thumb to not lower the car so much as to create a control arm angle below horizontal comes from. People somehow got the idea that a below-ground roll center was the kiss of death. Realizing the relationship just explained, they saw a way to prevent it from happening, i.e. don’t let the control arm sink below horizontal and the roll center can never descend below the ground.

I think it’s bunk. I ain’t skeered of below-the-ground roll centers.

Ok, maybe I’m a little scared!

Low roll centers do a really good job of banishing jacking force, one of three components of lateral weight transfer which we’ll talk about later. Jacking force produces loads on the suspension components that tend to jack up the sprung mass. This force gets smaller, however, the closer the roll center is to the ground. It turns negative and jacks down the car if the roll center goes below the ground.

One possible bad effect of transitioning between positive and negative jacking is that the forces in the suspension components reverse direction. Now, a control arm couldn’t care less, but all the joints might, especially if there were any play in them.

All modern performance cars have low roll centers. In fact, jacking force reduction is the primary way lowering this suspension reduces lateral weight transfer. If you aren’t calculating jacking force you’re nowhere, man.

For another thing, the control arm on my car as I’ve been running it is guaranteed to go below horizontal dynamically in bump and make the roll center descend below the ground, at least for a moment. The car seems not to explode.

Take a look at Figure 1 again. Notice that, at full droop, the arm is definitely slanting upward toward the center of the car. But, imagine that we mounted a wheel and dropped it off the jack-stands. The arm is going to be right about horizontal once the spring compresses. The idea that it could be kept above horizontal during it’s normal range of motion doesn’t seem credible to me.

I may be able to take some measurements and model how this actually occurs on my car. (If anyone already has the suspension measurements I’d like to have them.) In any case, I want to put some approximate numbers to what’s happening so I can do a first-order approximation to estimate the total effect on cornering power, as well as other factors, that result from lowering the car. Later, if I can get better numbers, I plan to refine the results.

Weight Transfer Reduces Cornering Power

Lateral weight transfer, by definition, is the transfer of load from the inside tires to the outside tires while cornering. Lateral weight transfer is important because it reduces total tire grip, or more precisely, total cornering power.

The four tires on your car work best when load is distributed evenly among them because, unlike what you were taught in high-school physics class, the load vs. friction (lateral grip) relationship is not linear in the real world where the rubber meets the road, so to speak. Unfortunately, equal load distribution is never the case when we want it to be, like when cornering or braking or accelerating or any other damn thing we are doing while driving the car, ordering your vente-mocha-espresso at the Starbucks drive-thru excepted.

How big is this effect? Carrol Smith, in Tune to Win, worked an example for a light race car and a particular tire performance curve. He found a 6% decrease in cornering power in an 80% load transfer case. Unfortunately, my car is clearly not much like the one he was working with.

Herb Adams, in his book Chassis Engineering, did the calculations for a 3,000lb car with 50/50 front to back weight distribution with 1000lbs of weight transfer while cornering at 1g. That’s 66.7% weight transfer, i.e. 1000lbs out of an original 1,500lbs on one side of the car transferred to the other side. His example has numbers very similar to my street-class Porsche 944 cornering on the sticky (and very expensive) street tires we use in autocross these days.

Herb’s method for calculating the weight transfer is less rigorous than what we’ll do, but what matters to me is that he found that the theoretical cornering power of 1.13g’s for the tire performance curve he used was reduced by weight transfer to 1.05g’s. That’s a 7% decrease for a 66.7% weight transfer. I will boldly make a linear relationship out of this data, namely that the cornering power will decrease 7% divided by 66.7% or about 0.1% for each 1% of weight transfer. This is an easy relationship for my feeble brain to remember.

By the way, the effect of lateral weight transfer is worse the farther the car is from 50/50 front-to-back because the heavy axle is affected more than the light one, making the two axles different in cornering power at different lateral-g levels. This affects the balance at the limit, making the car harder to setup and drive. It’s also why a weight distribution close to 50-50 is very nice to have. The 944 isn’t bad at all in that respect.

The main point for the autocrosser is this: if you reduce the lateral weight transfer the car should corner faster because the tires perform better. At least in theory. Except for the bad things that happen when you reduce weight transfer by lowering the car.

Calculating Weight Transfer

I’ve read several expositions of how to calculate lateral weight transfer, including Herb Adams’s and Carrol Smith’s mentioned previously, but the one I like the best is from Dennis Grant’s Autocross To Win website. He’s got a section entitled Weight Transfer and I highly recommend it.

A quick review: Grant calculates three sources of lateral weight transfer in a cornering automobile that add to produce a total value. He calls them the unsprung weight transfer, WTu, the sprung geometric weight transfer, WTg (also called jacking force) and the sprung elastic weight transfer, WTe. Each one gets it’s own formula that allows us to calculate it’s magnitude. Depending on what you do to the car, these values can change up or down.

In Figure 3, below, I’ve reproduced the formulas as Grant presents them. M is mass, LatA is the lateral acceleration. CGh is center of gravity height. RC means roll center. T is the track width.

![]()

Figure 3

Studying the equations we see that in order to calculate the total lateral weight transfer in a corner we need to know, measure or estimate the values for only seven variables: the unsprung mass (Mu), the sprung mass (Ms), the track width (T), the CG height of the car’s sprung mass, the CG height of the unsprung mass, the height of the roll center (RCh) and the value of the lateral acceleration (LatG) you think (or know) the car can generate. That’s it. You can use these equations roughly for the whole car, or for each end independently. Working each end independently will give insight into the roll distribution, front to rear, which is major when it comes to oversteer/understeer balance.

Now, I can hear Bubba Bratwurst asking, “Hey, it’s the lateral acceleration I want to increase, but I have to know the lateral acceleration in order to calculate the lateral weight transfer that I want to decrease. Isn’t that circular?” Yes, it is. But, it’s only a problem in your head, Bubba. Stick a number in for LatA and have another brat.

It’s also very easy to get the units messed up if you aren’t an engineer, or, even if you are. If you want to keep it simple and all you know (or want to know) about slugs (look it up) is that they’re slimy things that crawl in the dirt then here’s what you do: use the weight on the Earth’s surface (what the bathroom scale says) in pounds for mass, convert all inch dimensions to feet and use g’s for the lateral acceleration, as in 1g lateral, which I’m using here. Then you don’t need any conversion factors… they’re all built in and the answers are pounds of weight (vertical tire load) transferred.

If you want to do it in metric, go on ahead. (Bless your heart.)

Things we don’t need to know: how stiff your springs are, how stiff your anti-roll bars are, or, your shock forces. I expect more than a few of you might be surprised at that.

Don’t stiffer springs reduce roll? Yes. Therefore, weight transfer is reduced also, right? Nope. (Or, at least, not much.) Don’t believe me? Bless your heart.

Since spring rate, for instance, doesn’t appear in any of the three formulas, that means you don’t need to know your spring rates in order to calculate weight transfer. Same for horsepower, barometric pressure, phase of the moon or any other of an infinite number of parameters you care to think about. Not in the formula? Fugetabowdit.

Spring, shock and sway bar roll stiffnesses are important… I’m not saying they aren’t. They primarily affect how much of the total weight transfer goes to which end of the car and how fast it gets there after you make the boneheaded digital steering input that causes the front end to push out toward Saturn. They do not affect the total.

You might think about it like this: place a coil spring of 100lbs/in spring rate on the ground and set a 100lb weight onto it. How much weight does the ground under the spring feel? 100lbs, neglecting the spring weight, right? Now change the spring rate to 200lbs/in and put the 100lb weight back on top. How much weight does the ground feel now? Still 100lbs. The new spring only deflects half as much, but it transmits the exact same force to the ground.

Same thing in a car. The spring rate determines how far the car rolls, but doesn’t affect the value of the force that causes it to roll and it has nothing to do with how much weight is transferred due to the compression/extension of the springs.

Take a kart, for another example. Assume an infinite spring rate, which is almost correct since they don’t have a suspension. You don’t doubt that weight transfer still takes place do you? (See the unsprung weight transfer formula in Figure 3.) A passenger car has almost infinitely soft springs compared to a kart. Weight transfer still takes place, just in a more complicated manner. (All three equations from figure 3.) If you can take a variable in both directions towards infinity and nothing much happens then that variable isn’t important.

So, spring rate doesn’t affect weight transfer. This is what all the books say. Of course, all the books are slightly wrong. (Bless my heart.)

Or rather, they leave a little something out which may or may not be significant. I think the books are slightly wrong because the sprung mass of the car, as it rotates on the springs, is not absolutely constrained from moving laterally with respect to the tire contact patches. The sprung mass rotates about a roll center that’s usually (in a modern race car) very near the ground and therefore significantly below the CG, so the CG very definitely moves left and right as the car corners. This lateral movement of the CG that accompanies the rotation creates a little additional lateral weight transfer, just like the tool box in the trunk we forgot to remove would change the weight distribution during a corner if it slid to one side and how the gasoline in the tank sloshes, which we are also ignoring.

Our three equations don’t take this extra lateral movement into account. Neither did Smith or Adams or any other book on automotive suspensions that I’ve seen. A complete kinematic model of the car, which I imagine is the more usual way for a professional race team to do it these days, could include this effect, along with precise roll center movement.

I’ve never seen any numbers for the lateral CG movement; I have no idea how big it is. I think we can expect that the higher the CG is above the roll center and the softer the springs the more it will be. So, for an old-time race car with both a high CG and a high roll center (I hear they used to design suspensions that way) the effect on weight transfer must be vanishingly small. Such a car doesn’t roll much at all. (But, it will flip!)

For a modern race car, with a relatively low CG, low total roll, and a low roll center, it’s probably also very small. For a narrow and tall passenger car, say a 1970’s Saab 96, maybe not quite so small. In the mean time, like a typical engineer, I will arrogantly neglect any effect I can’t easily calculate!

(Yesterday I read Vivek Goel’s blog post on weight transfer in his blog Beyond Seat Time, which I highly recommend, in which he references a paper that does take the extra lateral movement of the CG into account. The author of the paper does a sensitivity study and concludes that the effect on weight transfer is negligible in all cases. I’m not totally convinced, but Ima-gonna-go with it for now.)

The Numbers

So, let’s estimate some numbers and put it all into a spreadsheet. I haven’t yet weighed or corner-balanced the car, so, for now, I’ll use the spec weight of 2900 lbs, not counting driver.

I have weighed the wheel and tire combination: 39lbs. Double that weight will be my estimate of the unsprung mass. That makes the unsprung mass total 2 x 4 corners x 39 lbs/corner = 312lbs. The sprung mass, Ms, is then 2900 – 312 = 2588lbs.

I know the average track, T, is 57.6”.

The CG height of the unsprung mass, CGhu, is usually taken as the wheel centerline height. For the stock wheels and tires that’s pretty close to 13”.

The CG height of the sprung mass, CGhs, is a little more difficult. I haven’t been able to find an actual measurement. I will guesstimate it at 20”. I’ve seen numbers like that for similar cars. For more modern Porsches, like the Cayman, I’ve seen a number in the 17” to 18” range, so 20” for the 944 seems reasonable. March of progress, you know.

The roll center height is another dubious number with no reliably measured values to be found. Several people are on record as saying the stock roll center is 4” to 6” above the ground, but they never say where or how they got it. I’ll go in the middle with 5”.

Now for the hairiest of the estimates. To calculate the effects of lowering the car we’ve got to know how much the roll center height changes as the sprung weight CG height changes. I have some real data for the double A-arm Corvette, but only hearsay for the strut/semi-trailing arm arrangement in the 944. Various sources (possibly not independent) claim 1” of sprung mass CG height change causes 2” to 3” of roll center height change. My initial guess from looking at the geometry is that the truth is on the high side of that range, so I’ll assume a 3 to 1 ratio to start with. Later, I’ll put in a 2 to 1 ratio to check the sensitivity. (The real change is probably not linear, either.)

So, for each inch of suspension-derived lowering we are going to say the roll center goes down 3”. That means the roll center is getting farther from the CG as the car is lowered. The distance between these two is the roll moment arm, so the arm is getting longer as we lower the car.

The lateral acceleration of the sprung mass during cornering produces the force on the end of the moment arm trying to roll the mass. A longer moment arm means more leverage at the roll center and, since I can’t change the resistance of the springs, the sprung mass portion of the car rolls farther. This is why lowering the car makes it roll more. What a pain!

Spreadsheet Results

The results of putting Dennis Grant’s equations and my values for the stock car into a spreadsheet are shown in the following figures. Figure 4, below, indicates that 1g lateral will produce 969lbs of total lateral weight transfer. So, 66.8% of the weight that was on one side gets moved to the other side. Using our previous tire performance estimate of 0.1% reduction in cornering power per each percent of weight transfer, we can calculate a value for the total cornering power reduction due to weight transfer of 6.7%.

Figure 4

Please notice that only 70lbs of weight transfer is from the unsprung weight. This is exhibited as a force that tends to pick up and flip the unsprung mass, just like a kart flips. 225lbs is geometric weight transfer (jacking force) which produces internal forces in the suspension components that tend to jack up the sprung mass. The vast majority, 674lbs, is elastic weight transfer, exhibited as roll of the sprung mass reacted by the springs and bars.

By the way, the 66.8% weight transfer is within 0.1% of the example given by Herb Adams. Maybe he was talking about a 944?

The first change I made to the car before I ever autocrossed it was to join the Tiny Rivals club (coined by Burglar on Rennlist in this thread, post 83) which had the effect of lowering everything by 1/2” while not affecting suspension geometry. The shorter tires reduce weight transfer and increase cornering power all by themselves, as seen in the “Short Tires” column in Figure 5, while not affecting anything negatively.

Figure 5

Total weight transfer drops 25lbs (from 969 to 944), most of which is a reduction in geometric weight transfer (WTg) which is directly proportional to the height of the roll center if you look at the equation. Elastic weight transfer (WTe) is unchanged because both the CG and roll center heights drop equally, maintaining the same moment arm distance from one to the other.

Next, I look at what happens if I take advantage of the M030 sport suspension and drop the overall ride height by 1” from stock, which then drops the roll center 3”, given our initial assumption. The results are shown in the “1” Drop” column of Figure 6.

Figure 6

Geometric weight transfer (WTg) has plummeted 158lbs (from 225 to 67.4) because the roll center height has moved down from the initial 5.0” above ground to 1.5” above ground. (The first 0.5” from the tiny Rivals, then 3” more from the 1” drop.) But, the elastic weight transfer has increased from 674lbs to 764lbs, a 13.3% increase, thanks to more distance between the CG and the roll center. This means the car will roll 13.3% farther than stock or with Tiny Rivals.

Unsprung weight transfer doesn’t change as compared to the short tires value and total weight transfer is reduced 70lbs (969 to 899) from stock. Cornering power reduction due to weight transfer has dropped 0.5% compared to stock, meaning we now have more cornering power, inspite of the increase in roll.

How about a 2” drop? Most people seem to think this is possible with the sport suspension, but probably too much if you can’t make other changes because of bump steer effects plus a roll center that gets too low. (OMG, it’s below the ground!) I actually don’t yet know how much lowering I can get.

At a 2” drop the weight transfer numbers look even better, as shown in Figure 7.

Figure 7

Geometric weight transfer (WTg) is now negative! (Anti-jacking.)

In spite of the anti-jacking making the geometric weight transfer go negative, it’s countered by a 26.7% increase in elastic weight transfer (WTe) as compared to stock, 854lbs vs 674lbs. This means 26.7% more roll than stock. Unsprung weight transfer doesn’t change and we are left with a total weight transfer decrease of 115lbs as compared to stock (854 vs 969). The total reduction in cornering power from weight transfer, as compared to stock, has decreased from 6.7% to 5.9%, meaning we have a net increase in cornering power of (100-6.7/100-5.9)-1 = 0.0086 or .86% (I think I did that right.)

How Much Time Saved?

How significant is a 0.86% increase in cornering power? Let’s put some numbers to it.

Each year at Dixie Tour there’s a 180 degree turnaround that’s about 160 feet in diameter. At 1g a car can negotiate that curve at 34.61mph. At 1.0086g (0.86% greater) that speed increases to 34.75mph. That extra speed saves 0.02s of time around that turn. Not really very much!

Similarly, if we assume that 25% of a 60s course is spent at max lateral-g, then the time saved over the course is 0.064s. While not nothing, and it could easily be the difference between 1st and 3rd, I’m having my doubts that it’s worth a significant decrease in roll stiffness and the loss of camber that would result.

How Sensitive Is this Result?

Remember that the preceding is predicated on a critical assumption, the 3 to 1 ratio of roll center movement to CG movement. What if it’s only a 2 to 1 ratio, as some have said?

For a 2 to 1 ratio we get a new, final chart, figure 8, below.

Figure 8

Notice a pattern? The decrease in cornering power reduction is exactly the same as before, going from 6.7% initially to 5.9% now, the same 0.8% improvement.

The big difference is the decrease in roll. The 2 to 1 ratio of movement creates only a 13.3% increase in roll as compared to 26.7% increase for the 3 to 1 ratio. So, the roll stiffness is very sensitive to how much the roll center actually moves w/r/t the CG height, but the weight transfer is not. These estimates show that I’ve got to have better information. I’ve got to nail down the actual ratio or I’m just spinning my wheels, so to speak.

Also, how do we know that we aren’t decreasing grip faster due to camber loss in roll than we are increasing it with reduced weight transfer? I’ll need to experiment and measure.

How does the roll center actually move? How bad is this extra roll and what does it actually do to transient response.? We’ll explore these questions in Part 2.

Thank you for the description of CG and RC. I’m planning on installing a watts link on a stick axle and this explained what will change in the car as it is run in different height adjustment positions.

LikeLike

Pingback: The Last 944 – Part 1 | Saving Time – An Autocrosser's Blog

Pingback: Compression vs. Rebound- Not What You Think | Saving Time – An Autocrosser's Blog